US patent 10056184; EPO patent 3365901; Indian patent 378739.

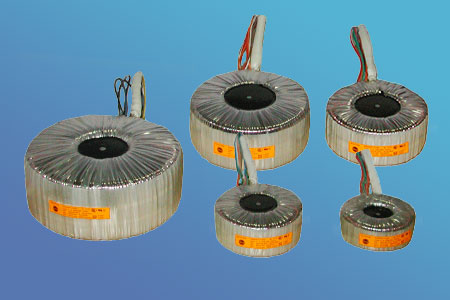

The typical method of manufacturing a toroidal transformer entails creating a steel core, insulating the core, winding magnet wire around the core to create a primary winding, insulate the primary, winding magnet wire over the insulation to create a secondary winding and insulating the secondary to complete the transformer. To mount the transformer, either a mounting washer and bolt are used, or the center of the transformer is filled with an epoxy with a hole for a bolt. Between each step of manufacturing, the transformer is handled and moves from one operation to the next.

Design and Construction of Segmented Core Caps

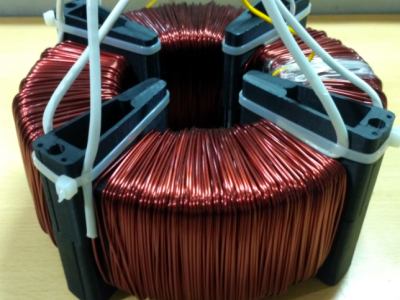

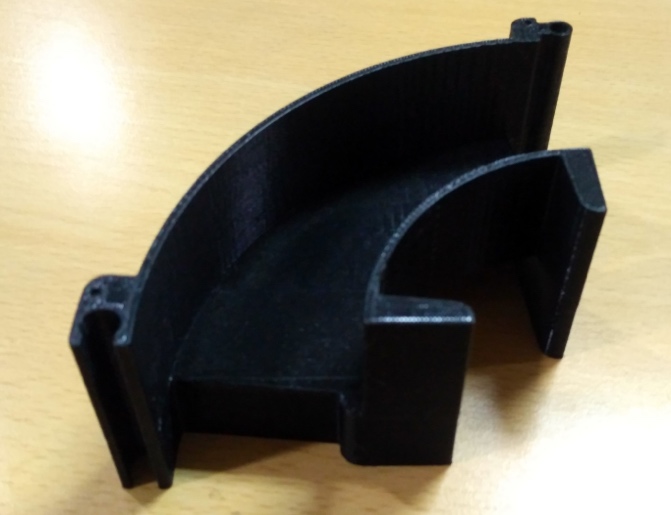

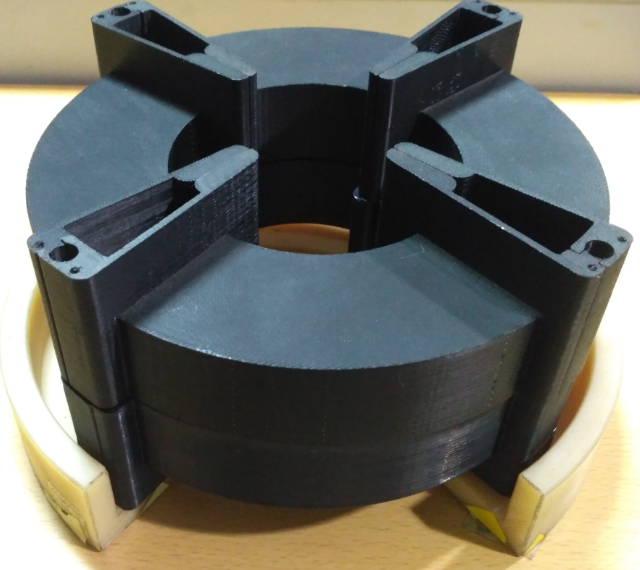

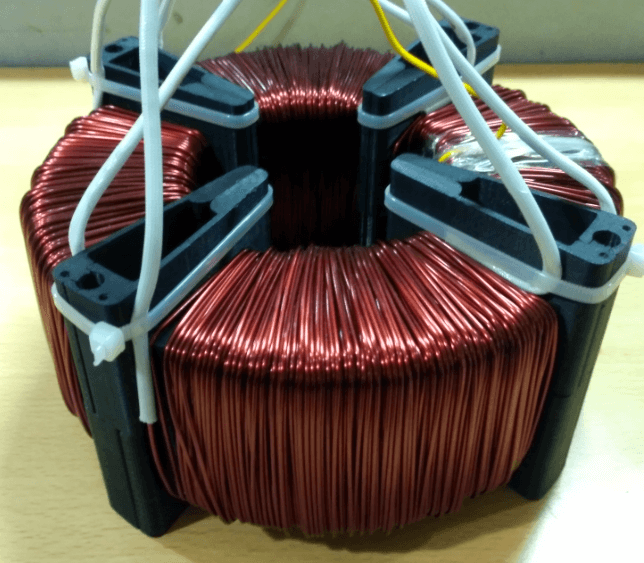

Segmented core caps support primary and secondary windings in alternate sectors to reduce leakage current. Several modular electrically insulating segments typically snap or otherwise join together to form annular or semi-annular core caps for covering or partially covering a ring-type toroidal transformer core. The segments or modules are typically made from Zytel® FR50, Rynite® FR530, or Zytel® E103HSL.

The core cap modules insulate windings from the core over the full range of the windings, and allow for double-wall insulation between adjacent windings, significantly reducing leakage current compared to conventional toroidal transformers. They also provide for direct cooling of the core by ambient or forced air without intervening insulation. The core cap may also be assembled from component modules over a completed wound toroidal core.

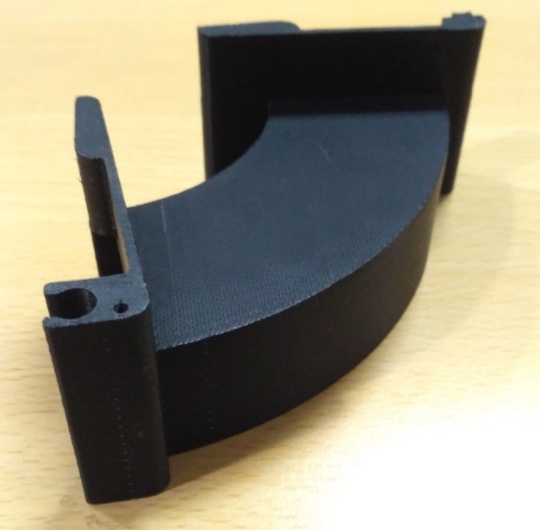

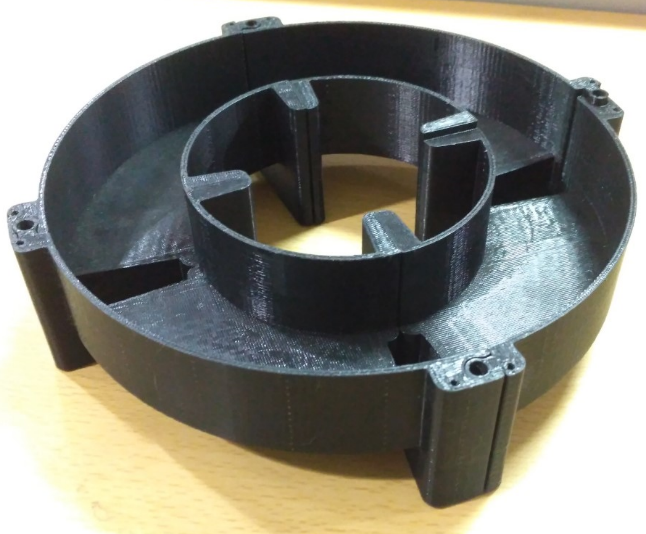

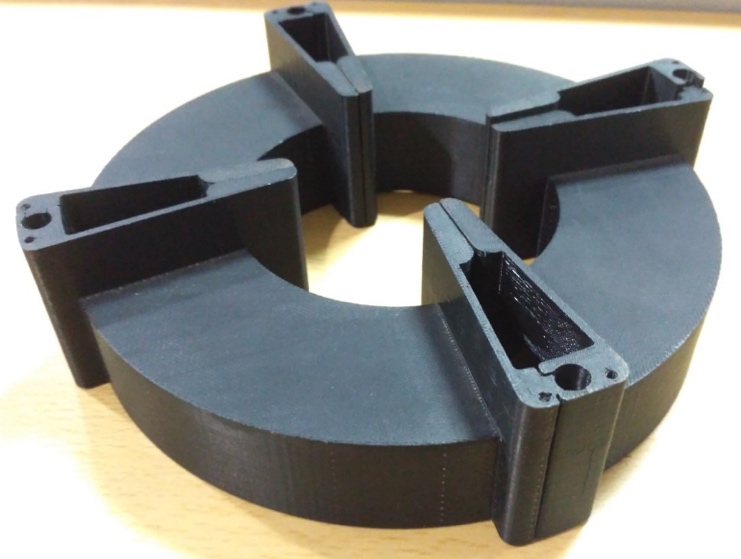

The segments of each module include a pair of spaced, typically electrically insulating, walls between which a core-covering panel portion is connected. The walls are disposed at a predetermined angle relative to each other, typically 30 degrees, 45 degrees, 60 degrees, or the like so that each modular segment spans an arc of about 30 degrees, 45 degrees, 60 degrees, etc. The respective spaced walls include engageable, typically male and female, connector portions, such that adjacently disposed segments may be repeatedly engaged with one another, with sufficient connected segment portions defining an annular core cap.

The number of segments required to complete a core cap is predetermined and is typically a function of the predetermined angle between the walls; for example, if the angle is 45 degrees, eight segments will be required to be connected together to define a ring shape. If the angle is 60 degrees, only six segments will be required to define a ring shape. While core caps are typically built from identical core cap modules, core caps may alternately include combinations of core cap modules spanning different arcs, such as four core cap modules spanning 45 degrees each and six core cap modules spanning 30 degrees each.

While identically sized and shaped modules are typically more convenient, there are no practical restrictions on the combinations of core cap module sizes and shapes that may be combined to yield a custom core cap having desired properties and characteristics.

Separating Walls

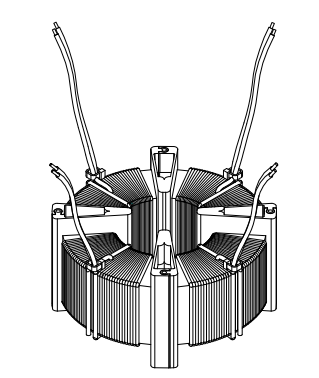

Typically, the walls engage the panel to define a relatively flat or flush core-engaging side or surface (defining the bottom or underside of the segment and ring) and disposed opposite the barriers established by two joined or locked together walls (defining the wire-segmenting or top side of the ring). The barriers define the parameters between which alternating wire windings are restricted, typically alternating primary and secondary windings.

The segments include one or more separation or wall positioned to partially or completely extend across the topside of the panel to further define parameters between which wire windings are directed. The one or more separations are typically positioned equidistantly between the walls and/or each other, respectively. The separations are typically oriented to extend radially outwardly from the center of the core and/or the annulus defined by the joined segments; in other words, each respective separation typically lies on a radius of the annulus, although the separation walls may have other convenient shapes and contours as desired.

The segments further include a core outer diameter or OD cover panel and/or a core inner diameter or ID cover panel, both extending downwardly so as to at least partially cover the OD and ID, respectively, of a toroidal core ring placed against the core cover panels of a partially or completely formed annulus. These panels may be flat for covering a core ring having flat outer and inner diameter sides or curved to follow a core ring having a rounded or curved inner and outer diameter portions.

The walls are truncated and do not extend across the panels. In some of these, lower walls are positioned opposite the panel from the respective wall. The lower wall may likewise include matable connectors for co-joining. Some of the segments include ribs positioned on the upper side of the panels, so as to generate an air gap between wire windings and the topside of the ring. The production of an air gap facilitates air cooling of windings by allowing air to circulate between windings and the topside of the cap.

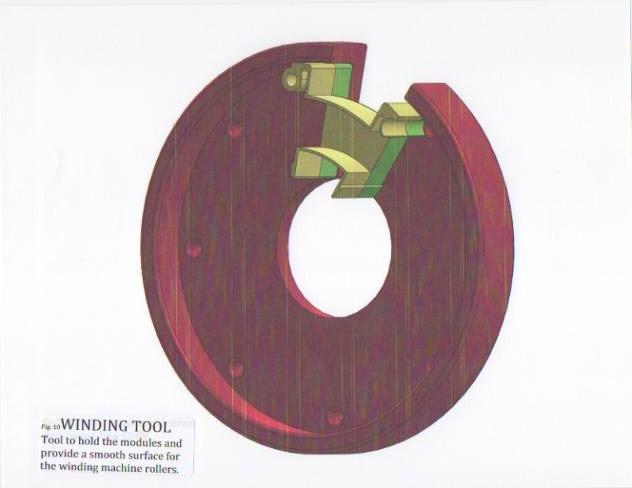

Segmented Core Cap Winding Tool

A winding tool is used to facilitate the winding of a capped core from a single bobbin. The winding tool is typically a flat ring having a projecting rim or flange extending from the outer diameter. The ring typically includes a slot, giving it a C-shape. The ring is sized to accept a segment, with the slot sized to pass wire onto the segment. The winding tool also typically includes an elongated arced wire lock member having multiple partial slots and one or more locking apertures for connecting the wire lock to one or more segments during the wire winding process

In operation, multiple segments may be connected to one another to define a ring. The ring includes an annular core top cover portion defined by the panels of the individual segments. In most embodiments, the ring also includes (typically) equidistantly spaced radial protrusions, defined by mutually engaged connectors, extending outwardly from the ring. Each radial protrusion is typically part of an elongated wall positioned on the top side of the ring and extending radially inwardly partway or completely across the topside surface. Some of the walls terminate in radial protrusions extending inwardly from the ring. These radial protrusions are typically formed from the joinder of two lower walls, although they may be formed separately.

The ring may also include an annular core, outer diameter cover and/or an annular core inner diameter cover, each cover positioned generally perpendicular to the core top cover portion and extending downwardly away.

The respective covers are typically composed of adjacent cover panels when the segments are connected to define the ring.

Typically, a pair of cap rings are constructed from connected segments and positioned on opposite sides of a toroidal core with outward protrusions aligned. An even number of segments are connected to make each ring. Wire is wound contiguously around alternating segments to define the primary windings, with N windings per segment. Wire is wound contiguously around the remaining segments, in multiples of N windings per segment, to define the secondary windings. Typically, all of the windings may be accomplished from a single bobbin or shuttle in one contiguous bobbin winding operation, with wire guided from one segment to the next through the groove or gap between the two opposite core caps. The wire is typically cut or severed to isolate the primary windings from the secondary windings, and the wound core may then be wrapped in insulation to define a toroidal transformer. In some of the winding tool may be utilized to facilitate core winding. Coils so wound retain the advantages of toroidal transformers while enjoying the benefits of being lighter, Smaller, more efficient and quieter than E-I laminate cores. Cores so wound exhibit reduced interwinding leakage current when compared with standard wound toroidal transformer cores.

Typically, the primary windings will occupy the odd-numbered segments, starting with the first segment wound, and the secondary windings will occupy the even-numbered segments. Each ring may contain multiples of three segments, such as six, nine, or twelve, and the core may be wound with primary, secondary and tertiary (not shown) windings as above to yield a three-phase transformer. Alternatively, the ring may contain segments having different configurations

An insulating material, such as a MYLAR strip, may be positioned to cover the portion of the core exposed by the gap, or the core may be partially or completely wrapped in an insulating material prior to the positioning of the cap(s) thereupon. In other designs, walls are spaced and oriented relative each other to define an annulus but are not physically connected to each other. All leads are double insulated/sleeved & attached with cable ties.

Summary: Segmented Core Cap Advantages

If a segment core cap can be designed that meets safety agencies specifications for creepage and clearance, then manufacturing time is reduced because:

- There is no need for ground and inter-winding insulation and also outer wrap

- The primary and secondary windings can both be wound on one machine reducing handling time

- Provided the cap includes mounting holes, the time to fill the center of the transformer with epoxy is not required.

If a segment core cap can be designed that is made of repeatable sections that “snap-together”, then the cost to tool and assemble the caps would be less because:

- The cost to tool a smaller part for injection-molding is less than the cost of tooling a larger part

- Assembling “snap-together” parts require less skill levels than other core insulation techniques

If an inexpensive tool can be designed to hold the segment core cap in place during primary and secondary winding, then the manufacturing costs will be less as existing manufacturing equipment can be used.

If a segment core cap transformer can be designed that meets safety agencies specifications for creepage and clearance and allows airflow around the core and windings, then the temperature rise will be less because:

- There is a direct path for heat to escape from the un-insulated core into the environment

- There is no inter-winding insulation and outer wrap that traps heat

- All windings have direct path for heat to transfer from them to the environment

If a segment core cap can be designed that includes mounting holes, then the weight of the transformer will be less because:

- No center epoxy will be necessary

- No mounting washer will be necessary

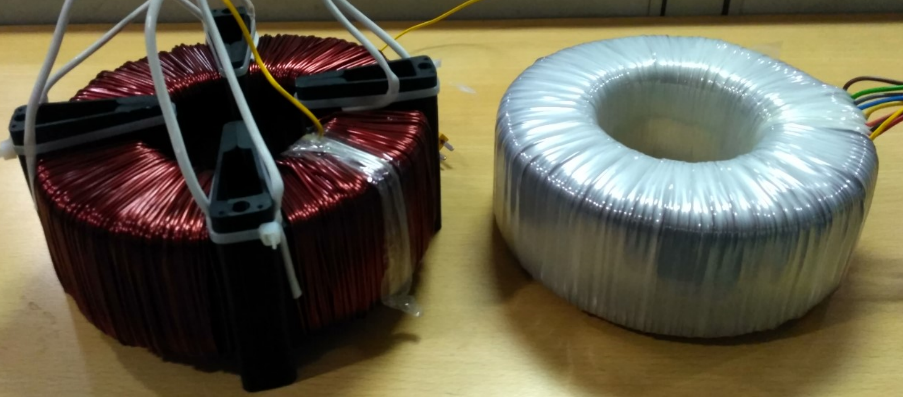

Segment Core Cap Transformer vs. Standard Toroidal Transformer

Segment Cap transformers offer significant reduction in leakage current and heat rise in comparison to standard toroidal transformers. Heat exchange is comparatively better on segment cap transformer since the design of the caps itself bestow all necessary insulations in place. It has been found in our experiment transformer of simple schematic (1:1 isolation txmrs) pose an advantage of 13~17°C over temperature rise.

Test Comparison / Power rating: 1500VA

| Test Parameters | Standard Toroidal construction | Segment Core Cap Construction |

| No load voltage @ 240 V | 239.64 V | 239.60 V |

| No load current @ 240 V | 36 mA | 48 mA |

| Core loss @ 240 V | 7.9 W | 8.8 W |

| No load current @ 264 V | 85 mA | 85 mA |

| Core loss @ 264 V | 12.0 W | 11.9 W |

| Max leakage current @ 264 V | 81 µA | 14 µA |

| Leakage @ Hi-pot 5 kV, 50 Hz, 2 sec | 1030 µA | 210 µA |

| Primary DCR @ 28°C | 0.719 | 0.779 |

| Secondary DCR @ 28°C | 0.784 | 0.781 |

| Output power @ thermal equilibrium | 1440 VA | 1425 VA |

| Input power @ thermal equilibrium | 1524 VA | 1519 VA |

| Efficiency | 94.49% | 93.81% |

| Surface Temperature | 111.5°C | 98.6°C |

| Ambient Temperature | 29.4°C | 30°C |

| Temperature rise | 82.1°C | 68.6°C |

| Mechanical Size | Ø200 × 90mm | Ø200 × 90 mm |

Weight Comparison

| Weight | Standard Toroidal construction | Segment core cap construction |

| Core | 7.80 KG | 7.80 KG |

| Caps | 400.0 Grams (Mylar) | 360.0 Grams |

| Copper | 1.90 KG | 1.95 KG |

| Center potting | 0.60 KG | – |

| Total | 10.7 KG | 10.1 KG |

Temperature rise comparison

| Power Rating | Temperature Rise (°C) | ||

| Standard Toroidal construction | Segment core cap construction | Difference | |

| 1500VA (Nominal) | 82.1 | 68.6 | 13.5 |

| 1800VA (Extended) | 108.3 | 91.5 | 16.8 |

Labor time comparison

| Standard Toroidal construction | Segment core cap construction | Difference |

| 100% | 66% | 34% |

Segment core cap transformer construction itself lend for better heat dissipation so they can be rated for extended power for the same volume which is the primary advantage. So, they are relatively smaller in size and lighter in weight compared to transformer of standard method of construction for the same power levels. Less leakage current, less manufacturing cost and cost-effective mounting design are the other advantages.

For example, below is a comparison of the 1500 VA segment cap transformer (Extended power 1800 VA) to our standard 1800 VA medical transformer of standard method of toroidal construction 1800MD-1-003.

Test Comparison

| Test Parameters | Standard Toroidal construction (1800MD-1-003) | Segment Core Cap Construction (Extended power – 1800 VA) |

| No load voltage @ 240 V | 247.35 V | 239.60 V |

| No load current @ 240 V | 55 mA | 48 mA |

| Max leakage current @ 264 V | 86 µA | 14 µA |

| Leakage @ Hi-pot 5 KV, 50 Hz, 2 sec | 1100 µA | 210 µA |

| Primary DCR @ 28°C | 0.414 | 0.779 |

| Secondary DCR @ 28°C | 0.480 | 0.781 |

| Efficiency | 94.50% | 93.50% |

| Surface Temperature | 120°C | 121.5°C |

| Ambient Temperature | 30°C | 30°C |

| Temperature rise | 90°C | 91.5°C |

| Mechanical Size | Ø210 × 100 mm | Ø200×90 mm |

Weight Comparison

| Weight | Standard Toroidal construction (1800MD-1-003) | Segment core cap construction (Extended power – 1800VA) |

| Core | 11.3 kg | 7.80 kg |

| Caps | 500.0 g (Mylar) | 360.0 g |

| Copper | 2.70 kg | 1.95 kg |

| Center potting | 0.50 kg | – |

| Total | 15.0 kg | 10.1 kg |

Labor time comparison

| Standard Toroidal construction (1800MD-1-003) | Segment core cap construction (Extended power – 1800VA) | Difference |

| 100% | 66% | 34% |

UL Approval for Segment wound construction

UL investigated the Segment wound construction transformer as per standards UL60601-1 1st Edition, ANSI/AAMI ES60601-1 1st Edition, CAN/CSA C22.2 No 601.1 M90 and CSA C22.2 NO. 60601-1 2nd Edition Construction and determined that segment wound transformer complies with the applicable requirements.

Talema UL file number: E251176

Conclusion

Although toroidal transformer designs are fairly mature in general, this white paper shows there is still room for innovation and improved efficiencies through the use of segmented core cap technology. We hope this piece of work is helpful for medical device manufacturers, magnetic designers, and anyone who may be interested.

For more information regarding segmented core cap technology or other medical grade magnetics from Talema, please contact us.

Learn more in our white paper — Improving Medical Isolation Transformers with Segmented Core Cap Technology