Medical grade isolation transformers are designed to isolate the patient and the operator from an electric shock and to protect the equipment from power surges or faulty components.

For the safety of the patient in hospitals, all diagnostic or therapeutic medical equipment (medical electrical devices and non-medical electrical devices in the patient’s environment and areas for medical use) should be completely isolated from the supply line using strengthened isolation. Complete patient/operator safety is assured by medical-grade isolation transformers with very low leakage current (IEC 60601-1 medical electrical equipment).

Medical grade transformers are designed to isolate the patient and the operator from an electric shock and to protect the equipment from power surges or faulty components.

Medical grade transformers also maintain strict adherence to the following:

- Maximums on earth, patient or enclosure leakage current

- Compliance to the harmonized IEC 60601 standard

- Minimums on creepage distance and air clearance

- Maximum temperature rise

Benefits of Medical Grade Transformers

- reduced safety testing time allowing for faster time to market

- low leakage current

- guaranteed compliance with international safety agency standards

- compact size

- reduced weight

- low power losses

- built-in thermal protection

A secure galvanic separation is provided from the public power supply, within the leakage current limits of connected devices. The low stray magnetic fields and fault-tolerant design makes these transformers suitable for use near monitors. They are not only an ideal solution for medical diagnosis or medical electronic devices, but they can also be used in IT equipment and video systems in the patient environment.

Isolation Design Methods

Medical grade isolation transformers use two design options to achieve isolation: safety ground, and reinforced insulation.

Safety Ground — Safety ground transformers utilize standard transformer isolation. A safety shield between the primary and secondary coils, with insulation between the shield and each coil, maintains leakage current maximums. The safety shield has to be thick to be able to meet required tests in the safety standard. If the isolation breaks, the electrical path goes directly to ground, providing safety.

Double/Reinforced Insulation — For a transformer that relies on double or reinforced insulation there is no “safety” shield, but the insulation, as indicated by the name, is much thicker. It is designed so that all layers of the insulation can pass the thickness and high potential voltage tests required by the standard. If one insulation layer breaks, the next layer will be able to provide the required safety.

In both design options, the construction design must still meet the required creepage and clearance requirements. If the transformer includes a static shield for noise reduction, it is important to note that this shield does not provide the transformer with safety ground but rather works as a functional earth. When the shield is grounded, it attenuates the common mode noise and can reduce the leakage current from the primary to the secondary winding (please note that this leakage reduction is not the same as when measured primary to ground).

Normally, without extra mechanical barriers between the primary and shield and secondary, a transformer with double/reinforced insulation has lower leakage current than the one with a safety shield.

A safety shield wire should be connected to the protective earth terminal in the equipment while the static shield, if included, should be connected to the functional earth terminal.

Medical Grade Isolation transformers are mostly used in a 1:1 ratio (the primary voltage rating equals the rated secondary voltage value). The two windings will have the same number of turns. There might be a slight difference in the number of turns to compensate for voltage drops; otherwise, the secondary voltage would be slightly less than the primary voltage.

By using isolation tape and a screen winding between the primary and secondary windings the required dielectric strength of ≥ 4 kV for reinforced and double insulation is achieved, plus the required “general earth leakage current” of < 100 µA is also achieved.

Talema Medical Grade Isolation Transformers

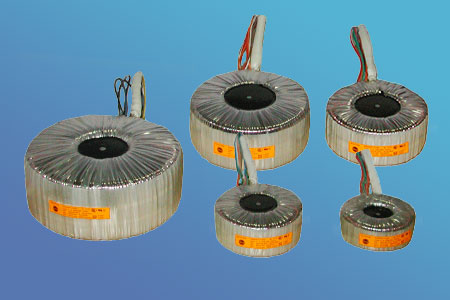

Talema designs and manufactures medical-grade isolation transformers for 240/120/100 V and 240/120 V rated for up to 3000 VA (standard range) and up to 15 kVA (custom designs). Talema isolation transformers offer reinforced safety for use in medical electronic devices. Our safety specifications are well within the recommended standards and adhere to the compliance guidelines as stipulated by IEC and UL safety standards.

See the following page on the Talema website for more information:

Medical Grade Toroidal Transformers

Improving Medical Grade Transformer Design

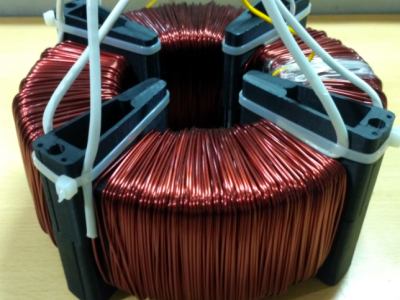

As previously discussed, standard toroidal transformers are more labor-intensive than standard EI transformers as the construction does not lend itself to automation. Also, they employ a thicker mid insulation construction to meet the leakage current requirements specified by the safety standards. Thus, there is a need for a toroidal transformer to be designed to overcome these drawbacks.

Segmented core cap technology addresses these needs. By using specially designed core caps that provide the insulation benefits of a bobbin (linear construction), manufacturing costs can be reduced and other advantages of leakage current, temperature rise, and weight reduction can be achieved.

We will discuss segmented core cap technology for medical isolation transformers in our next article in this series

Learn more in our white paper — Improving Medical Isolation Transformers with Segmented Core Cap Technology