A transformer basically is a very simple static (or stationary) electromagnetic device that works on the principle of Faraday’s law of induction by converting electrical energy from one value to another.

A transformer does this by linking together two or more electrical circuits using a common oscillating magnetic circuit which is produced by the transformer’s core. A transformer operates on the principle of electromagnetic induction in the form of mutual induction.

Mutual induction is the process by which a coil of wire magnetically induces a voltage into another coil located in close proximity to it. Therefore, we can say that transformers work in the “magnetic domain” and transformers get their name from the fact that they “transform” one voltage or current level into another.

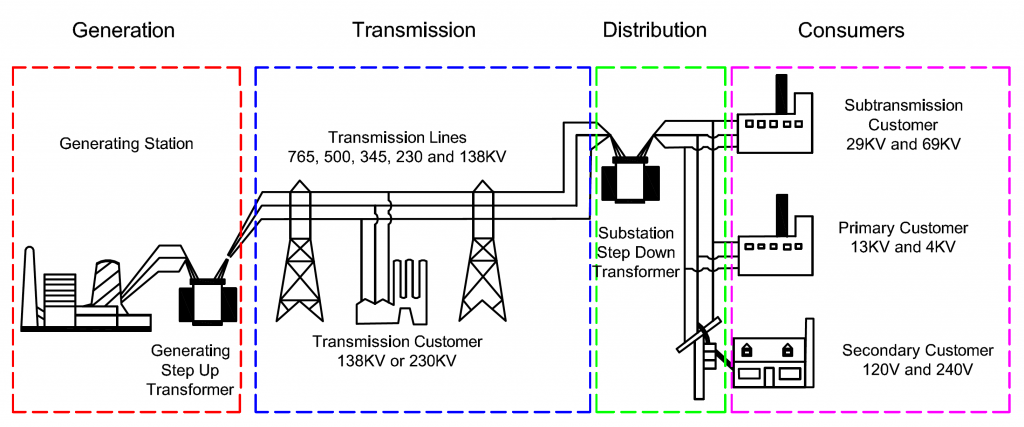

How Transformers Enable Long-Distance Power Distribution

Transformers are important building blocks in the electrical network for the transmission and distribution of power. Stepping up and down AC voltages to any level is possible with the transformer thanks to Faraday’s law of magnetic induction.

Generated AC voltages are easily transformed into much higher voltages using step-up transformers and then distributed across vast distances using a grid of pylons and cables. The reason for transforming the voltage to a much higher level is that higher distribution voltages imply lower copper losses (I² × R) along the networked grid of cables.

The higher AC transmission voltage is then reduced to a much lower, safer, and usable voltage at its destination, where it can be used to supply electrical equipment in our homes and workplaces.

Transformer Working Principles

A transformer is a static electrical device that transfers electrical energy (AC) from one circuit to another circuit without a change in its frequency. Commonly, transformers are used to increase or decrease the voltages of alternating current in electric power applications.

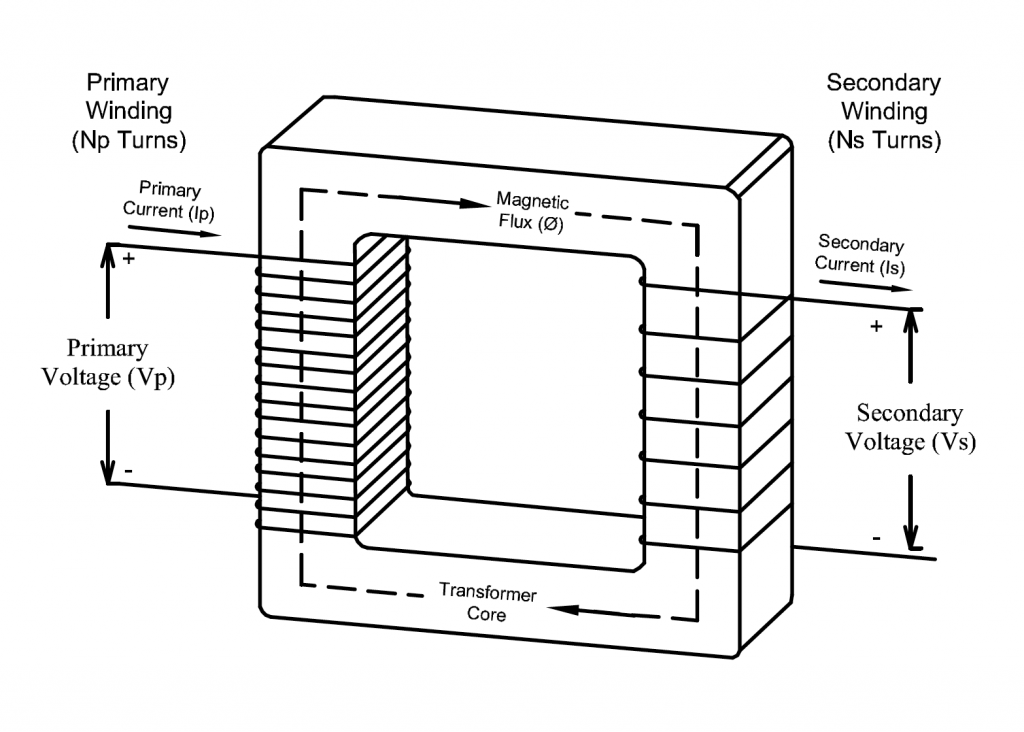

A single-phase voltage transformer basically consists of two electrical coils of wire, one called the primary winding and another called the secondary winding. The primary side of the transformer is the side that usually takes power and the secondary is the side that usually delivers power. In a single-phase voltage transformer, the primary is usually the side with the higher voltage.

These two coils are not in electrical contact with each other but are instead wrapped around a common closed magnetic iron circuit called the core. The two coil windings are magnetically linked through the common core allowing electrical power to be transferred from one coil to the other. This soft iron core is not solid but made up of individual laminations assembled together to form the core structure.

A single-phase transformer can operate to either increase or decrease the voltage applied to the primary winding. When a transformer is used to increase the voltage on its secondary winding with respect to the primary, it is called a step-up transformer. When it is used to decrease the voltage on the secondary winding with respect to the primary it is called a step-down transformer.

- Primary winding – produces magnetic flux in the core when connected to an electrical source (the primary current).

- Secondary winding – outputs the secondary current generated by magnetic flux in the core.

- Transformer core – provides a low-reluctance path through which magnetic flux can move from the primary winding to the secondary winding, creating a closed magnetic circuit.

The energy efficiency of a transformer depends on core losses and copper losses within it. Core loss depends on voltage and copper loss depends on current. Core loss is further divided into hysteresis loss and eddy current loss and it merely depends on the magnetic properties of the core material and core construction.

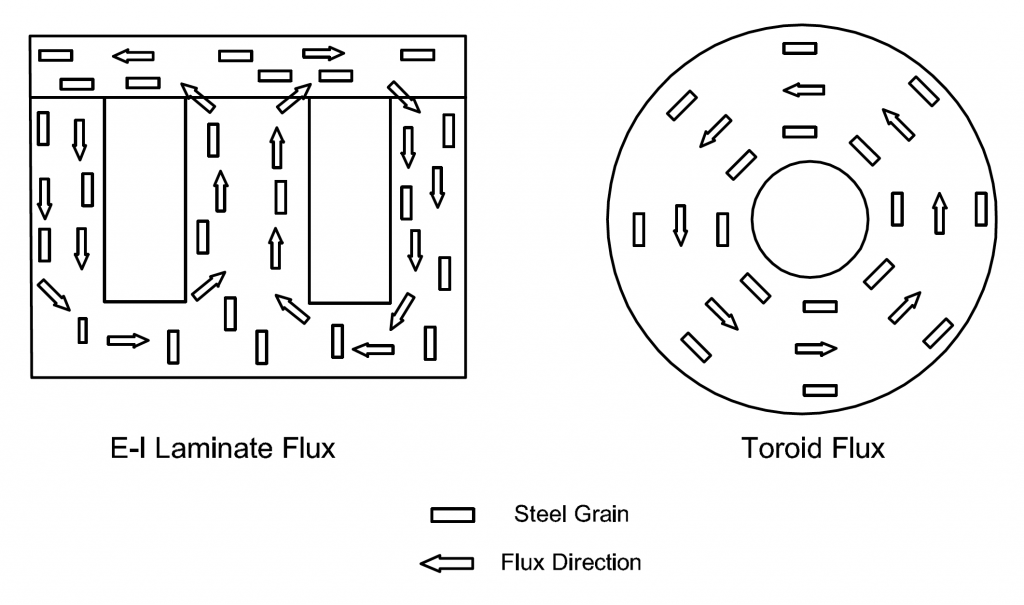

For most transformers designed for use within homes or offices, one of two styles of transformers is used. They can be made with either an E-I laminate or a toroidal core.

Standard E-I Transformer Construction

In an E-I structure, the matching “E” and “I” components are stamped from sheets of thin grain-oriented electrical steel that are later stacked to create the core. The primary and secondary windings are wound on bobbins. Multiple bobbins are placed on spindles and spun in order to apply the windings.

This method of using bobbins allows for automation that reduces the manufacturing times and also provides insulation between the windings and the core. The E-I core laminations are stacked inside the bobbins to complete the transformer. Their ease of construction makes standard E-I transformers very economical to manufacture, which is their primary advantage.

Although economical to manufacture, standard E-I transformers do have several limitations. As the punched laminations are stacked to form the core structure, small imperfections and burrs in the butting edges of laminations create an effective “air gap” which reduces the operating flux levels. Decoupling of windings is more common with linear construction, and as a result, leakage inductance and stray capacitance are naturally higher. Additionally, the loose laminations will vibrate at the fundamental frequency, which introduces disturbing hum (mechanical noise). All these disadvantages result in a transformer of larger size with less efficiency.

Conclusion

Our modern world of efficient power distribution across cities and continents would not be possible without electrical transformers. Standard E-I construction provides an economical solution that meets many power conversion needs, but they are not without their disadvantages in terms of size, weight, and efficiency.

Next in our series on toroidal transformers, we will discuss the construction of toroidal transformers and their performance advantages over standard E-I construction.