In today’s performance-driven world, magnetic components lie at the heart of the systems, devices, and networks that we rely on daily. These components are crucial for essential services across various sectors including telecommunications, industrial applications, military and aerospace, automotive, oil and gas, medical, and renewable energy.

As electronic solutions evolve in sophistication, there is increasing pressure on organizations and designers to enhance performance while minimizing costs. Electronics depend on power supplies, whose design and management affect their efficiency, reliability, safety, and cost. Customization of magnetic components is a strategy we advocate for addressing these needs.

What exactly are custom magnetics, why do they surpass standard off-the-shelf products, and why is it critical to collaborate with a trusted development partner capable of managing a complex supply chain network?

Understanding Custom Magnetics

Rising user expectations and stricter regulatory demands are compelling manufacturers to develop products that are not only more reliable and safe but also more functional and efficient. In light of these requirements, design teams are tasked with optimizing essential components and adjusting them to achieve optimal performance.

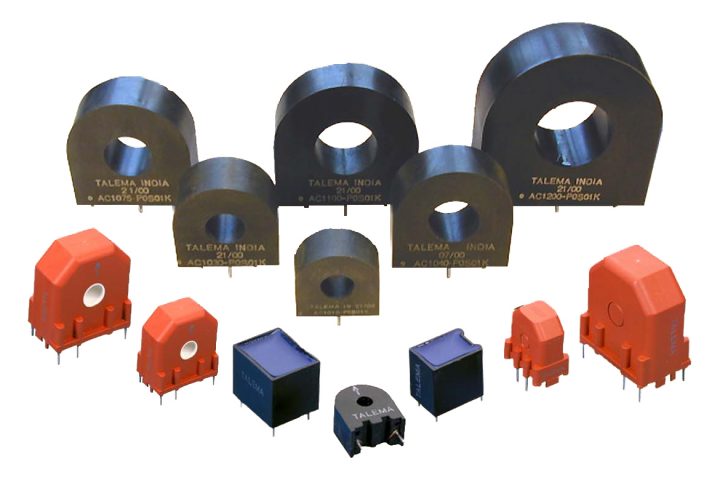

Custom magnetic components can be anything from Signal Transformers and Power Filter Inductors to Common Mode Chokes, LAN, and xDSL Modules. These components are crafted to meet specific customer needs, with the goal of delivering innovative solutions that are both timely and cost-effective.

In the domain of magnetic components, precision is paramount. Adhering to precise and timely manufacturing methods is crucial for success. Through customization, manufacturers have the opportunity to collaborate closely with their clients, selecting the right materials to enhance performance, longevity, and sustainability.

How Off-the-Shelf Parts Compromise Innovation

Choosing between customizing a component and selecting an off-the-shelf option is a significant decision that influences the design, manufacturing, and deployment stages. Customization provides flexibility; for instance, producing customized inductors, transformers, or chokes allows design teams to precisely control performance parameters, while senior leaders maintain a comprehensive overview of the entire process from design to implementation.

There’s a common misconception that customization is only viable for small-batch orders. The term ‘mass production’ often brings to mind limitations associated with off-the-shelf products. However, mass production can also be integrated into the customization process. With a strong supply chain network, components can be customized for any size order, ranging from five to five million parts, thereby accommodating varying demands.

Moreover, customization ensures that whether responding to a small batch requirement or ramping up production to address a spike in demand, manufacturers can maintain quality across the supply chain and adapt to continuously changing market needs.

Customizing magnetic components for specific applications not only offers more creative freedom in product development but also provides a competitive edge over those who rely solely on standard solutions. Nevertheless, external factors like the consistent availability of materials must be considered to meet production schedules and customer expectations.

Navigating Supply Chain Disruption

Customization necessitates a robust supply chain network, which is essential for the production process. Manufacturing custom components requires sourcing unique materials that adhere to specific quality standards and are delivered within stringent deadlines. Without a well-coordinated and resilient supply chain, meeting customer expectations is nearly impossible.

The use of non-conflict materials must be a standard practice, ensuring they are sourced, produced, or utilized without contributing to conflict, human rights abuses, or environmental degradation. However, sourcing these materials has become challenging due to geopolitical tensions, such as the war between Russia and Ukraine and conflicts in the Middle East between Israel and Gaza. These conflicts lead to trade disputes and sanctions that disrupt the flow of raw materials, causing price volatility and supply chain interruptions.

Moreover, there is growing pressure on manufacturers to align with sustainability goals, which prompts organizations to reevaluate their material sourcing strategies. As consumer awareness of environmental and social impacts increases and regulators demand greater accountability, we have significantly invested in our manufacturing networks by establishing a presence in various global locations. This strategy allows us to ethically source materials from multiple regions, reducing our reliance on areas prone to volatility.

Collaborating with a trusted development partner is crucial for navigating the complex geopolitical landscape of today. Customers seek certainty in their decisions and assurance that disruptions caused by conflicts or regulatory issues will not affect the delivery of parts. Diversifying our supplier base and production facilities minimizes risks and guarantees consistent quality and service in production.

Embracing the Future of Magnetic Component Manufacturing

Customization positions organizations to lead in the future of electronics and component design. It provides flexibility, efficiency, sustainability, and a competitive edge in a competitive market. This approach enables design teams to construct components tailored to the demands of today’s performance-driven applications, making full use of the latest technologies and solutions.

Partnering with a dedicated development partner who boasts a proven track record and a robust supply chain network is essential to navigate the complexities of the geopolitical landscape and to deliver innovative solutions. Instead of settling for off-the-shelf components, choose to embrace the future of magnetics manufacturing through customization.