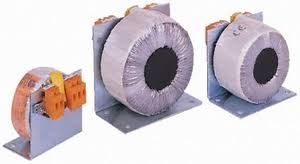

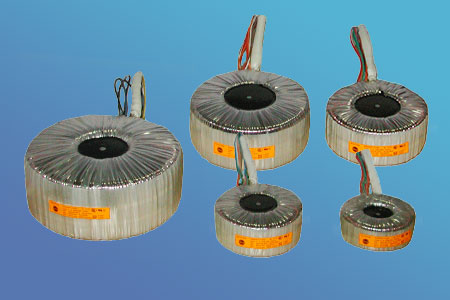

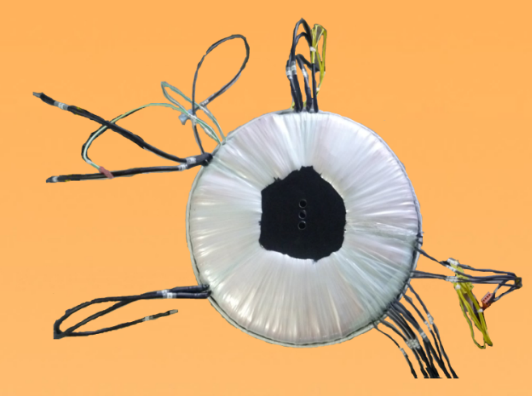

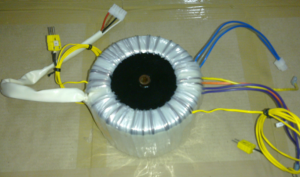

A toroidal transformer is a special type of electrical transformer with a doughnut-like shape. Toroidal transformers provide increased design flexibility, efficiency, and compactness when compared to traditional shell and core type transformers. They are an ideal solution for low-KVA (up to 15 KVA) rated devices and equipment used in medical, industrial, renewable energy, and audio applications.

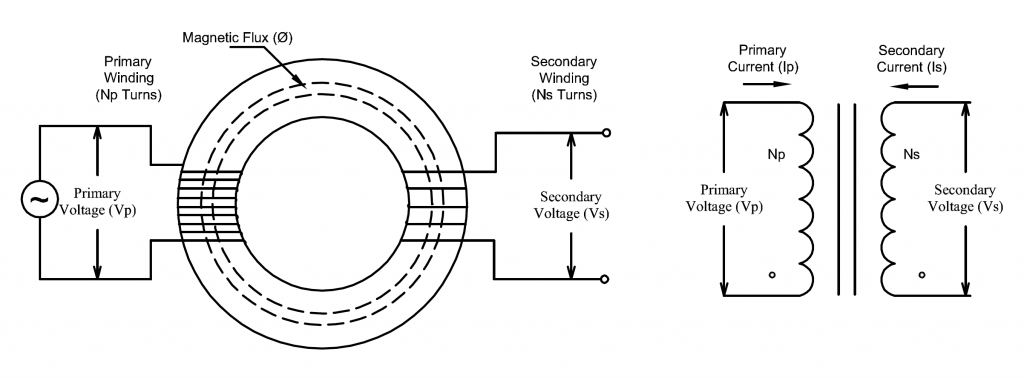

A toroidal transformer operates under the principles of electromagnetic induction similar to a linear transformer. It features a toroidal core surrounded by primary and secondary windings. As current flows through the primary winding, it produces an electromagnetic force (EMF) that generates a current in the secondary winding; this process allows power to be transferred from the primary coil to the secondary coil.

Comparison Between Toroidal Transformers and Conventional Laminated Transformers

Toroidal transformers are typically known to be lighter in weight and smaller in size when compared to conventional transformers.

Volume and Weight

All windings in a toroidal transformer are symmetrically spread over the entire core which makes the wire length very short. A higher flux density is also possible as the magnetic flux is in the same direction as the rolling direction of the grain-orientated core, allowing significant savings of volume and weight. A higher current density can flow through the wire as the whole surface of the toroidal core allows efficient cooling of the copper windings. This smaller size makes it more useful for compact electrical products.

Efficiency

The ideal magnetic circuit of the toroid, together with the ability to run at higher flux density than E-I laminates, reduces the number of turns of wire required and/or the core cross-sectional area. Either benefit reduces losses. Toroidal transformers typically are 90 to 95 percent efficient, whereas E-I laminates have a typical efficiency of less than 90 percent. In recent years, more attention has been given to the energy efficiency of electrical equipment. Legislation has been considered which would encourage minimum efficiency standards for all types of electrical products, with lighting and computer equipment being the most prominent. Toroidal transformers will likely serve as a method for achieving compliance with these new energy efficiency standards.

Transformer Hum

Audible hum is caused in transformers when the windings and core layers vibrate due to the forces between coil turns and core laminations. Moreover, the hum increases over time as the laminations start loosening. But the construction of toroidal transformers helps to dampen acoustic noise. The core is tightly wound, spot welded, annealed, and coated with epoxy resin or insulated with Mylar tape. The uniform winding of the core leaves no air gaps, thus leaving no loose sheets to vibrate, ultimately resulting in less hum. Even if the hum is heard when the power is turned on, it goes down to a quieter level after a few seconds. In addition, the high quality of the grain-orientated silicone alloyed electric steel makes the magnetostriction very low, thus allowing hum to be almost completely eliminated.

Stray Field

Stray field in toroidal transformers is approximately 85-95% lower than in conventional laminated transformers. Achieving low levels of stray field is an important consideration for the equipment designer as the phenomenon can create unwanted noise through interference with sensitive electronics. A toroidal transformer will generally offer a reduction of 8:1 in magnetic interference levels compare with traditional frame style laminate types.

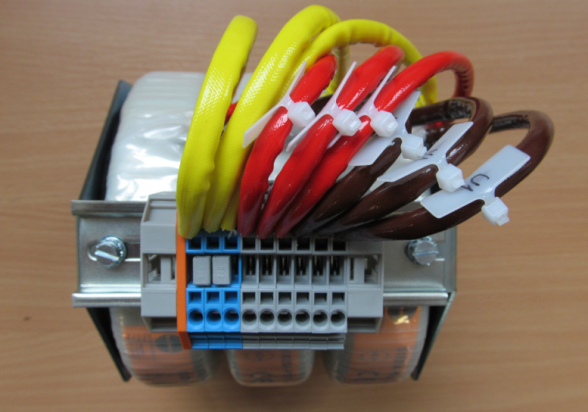

Dimensional Flexibility

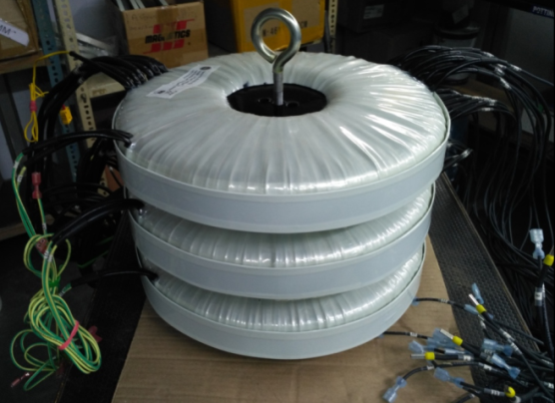

Toroidal transformers offer a high degree of dimensional flexibility compared with conventional laminated transformers. Toroidal cores can be produced in virtually any diameter or height.

Magnetizing Current

Iron losses in a toroidal core are very small, typically 1.1 W/kg at 1.7 Tesla and 50 Hz. These low iron losses result in very small magnetizing current, which contributes to the typically excellent temperature ratings of toroidal transformers. This results in a heavy reduction of the ‘no-load’ power loss, which makes the toroidal transformer very efficient.

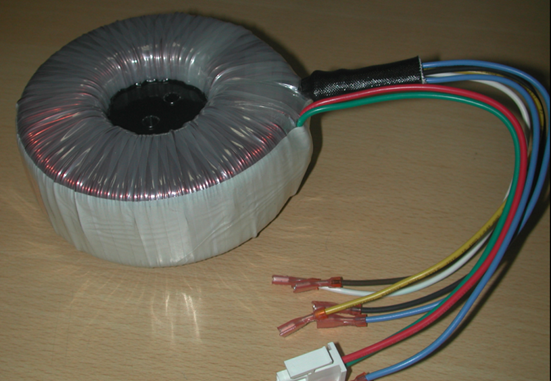

Ease of Mounting

Standard mounting for sizes up to 1000 VA is with a single metal centering washer and mounting screw or bolt making installation quick and simple.

Other popular mounting methods include:

- Resin center potting with brass inserts or through-hole

- Pressure-less mounting plates

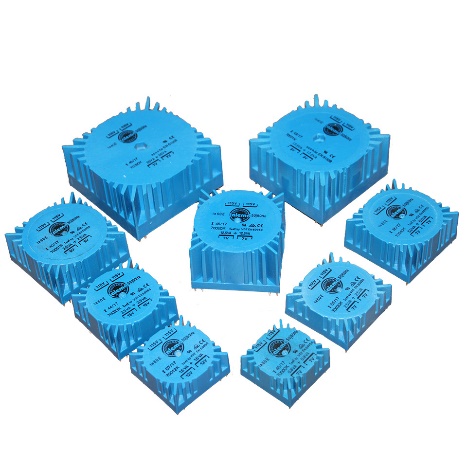

- Complete encapsulation in plastic or metal housings

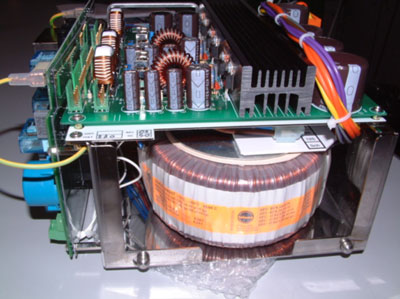

- PCB mounting (through-hole)

- DIN rail mounting

Toroidal Transformer Application Areas

Toroidal transformers can be designed and manufactured to a wide range of specifications to suit numerous applications. Below are some typical application areas along with examples Talema has produced for these applications.

General purpose Transformers for Universal applications

Audio and Video Equipment

High-End Audio Systems

Medical Equipment (Isolation Transformers)

Inverters and Chargers

Welding machines

Electromechanical Testing

Locomotive HVAC Systems