Toroidal Transformers

Current Transformers

Change Notification

Toroidal Transformers

Talema Toroidal Transformers meet modern day requirements for a small-size, low–magnetic interference field transformer. Featuring a nearly ideal physical construction, the design engineer can expect excellent performance. Small size and weight (approximately 50% that of conventional transformers), extremely low noise and low magnetic interference field make the toroidal transformer ideal for compact power supplies.

Volume & Weight

The toroidal core has the optimal shape for producing a transformer with the minimum of material. Because the quality of the core is such a vital consideration for sensitive applications, Talema has invested heavily to provide extensive core manufacturing, annealing and testing facilities.

All windings are symmetrically spread over the entire core which makes the wire length very short. A higher flux density is possible as the magnetic flux is in the same direction as the rolling direction of the grain orientated core allowing significant savings of volume and weight. A higher current density can flow through the wire as the whole surface of the toroidal core allows efficient cooling of the copper windings.

The iron losses of the toroidal core are very small, typically 1.1W/kg at 1.7Tesla and 50Hz, giving very small magnetizing current, which contributes to the excellent temperature rating of the toroidal transformer.

Efficiency

The toroidal shape gives a significantly higher efficiency compared to conventional transformers of the same size. The advantage is either an increased output power with the same size or a lower weight and smaller size at the same output power.

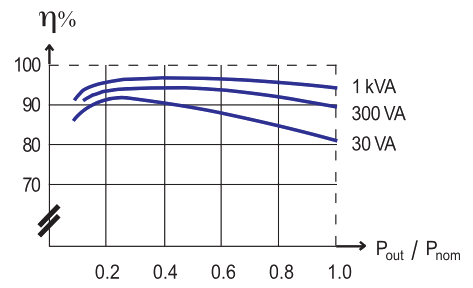

Figure 1 shows typical efficiency which can be expected as a function of the power relationship Pout / Pnom and transformer size.

Transformer Hum

Because there are no air gaps, there are no loose sheets which can vibrate. In addition, the high quality of the grain-orientated silicone alloyed electric steel makes the magnetostriction very low, thus allowing the disturbing hum found in most common types of transformers to be almost completely eliminated.

Delivery

Various production facilities allow fast delivery and ensure continuity of supply to our customers.

Mounting Details

For sizes up to 1000VA, a low cost assembly can be made with a centering washer and a center screw or bolt. Transformers in the range of 15VA through 500VA can also be potted in standard Polyamid housings. All transformers can also be center potted – either with a center hole or with a threaded insert.

International Quality Approvals

Talema has invested considerable time and effort to obtain “family approvals” enabling automatic recognition of custom transformers without having to send each new design to a certified test facility for approval, saving the customer both time and money. UL Recognized components, DEKRA Approvals to European Standards, and IEC CB Certificates for worldwide approvals.

Full details of our UL files , DEKRA EN61558 approvals, and IEC 61558 approvals

Factory Approvals

Our Corporate responsibility page has full details of factory approvals to ISO9001, ISO14001, ISO45001, together with our RoHS, REACH, WEEE, Conflict Minerals, and California Proposition 65 compliance statements.

Production program

Standard Distribution: Open wound, Standard and Mini; Encapsulated; Print & DIN Rail Transformers -230V primary, with ENEC KEMA-KEUR marking; Customer standards: Open wound, Encapsulated, Print, DINRail, a wide range of secondary voltages and mounting styles.

- Power: 1.6VA – 7.5kVA per phase

- Special sizes; extremely flat or small diameter, i.e., up to 250VA with 96mm O.D. for European P.C. formats

- Electrostatic copper shielding

- Assembled 3 phase sets

- Magnetic shielding

- Potting in special housings for sizes up to 1.2kVA

- Secondary voltages available up to 1kV

Frequency range

TALEMA Standard Transformers are designed for operating frequencies between 48 Hz and 60Hz and operate up to 450 Hz maximum. With increasing frequency, the transformer size decreases accordingly. Core materials for frequencies up to 100kHz are available in materials such as thin tape wound nickel alloy, molded powder or sintered ferrite.

In-rush Current

Due to lack of air gaps, toroidal transformers generally have a higher inrush current than normal transformers. For mains fuses we recommend the use of slow blowing types, especially for output power rates in excess of 500VA.

Voltage Drop

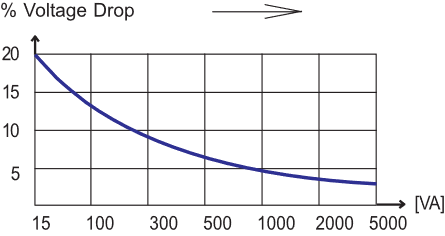

The secondary voltages and currents are valid for normal output power. At partial load the output voltage, as a function of transformer size, will be accordingly higher. Figure 2 shows the voltage increase for TALEMA Standard Toroidal Transformers at no load conditions. (Also known as Regulation)

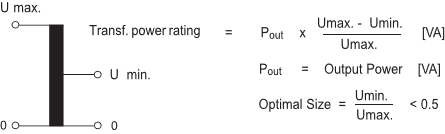

Autotransformers

An autotransformer allows smaller dimensions and a more economical over all design in cases where galvanically separated windings are not required.

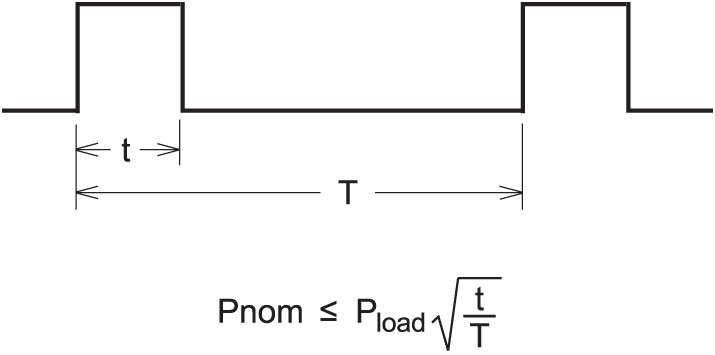

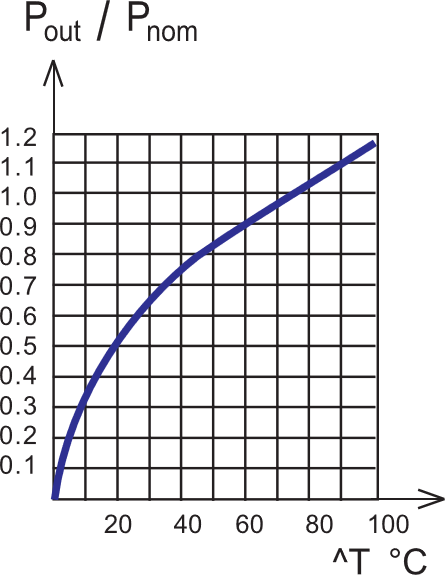

Duty Cycle

A smaller transformer can be used if the load is intermittent. Because the output power in this case significantly exceeds the norminal power, the secondary voltage drops below the voltages shown on page 8. The voltage drop increases proportionately with the current being drawn (figure 4).

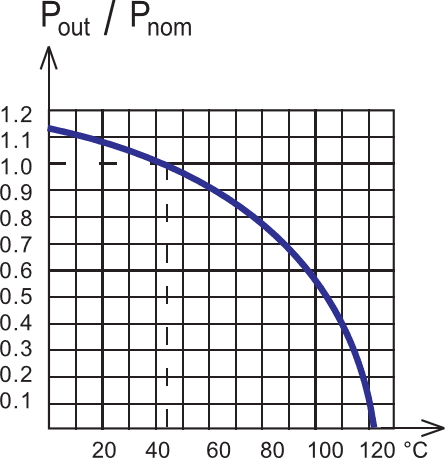

Temperature rise

As can be seen from graphs in figures 5 and 6, TALEMA Standard Toroidal Transformers are designed for a temperature rise of 60°C to 70°C at nominal load. When choosing a transformer size, the ambient temperature and heat sink coefficient of the mounting place must be taken into consideration. Figures 5 & 6 show the typical temperature change which occurs as a function of output power or overload.

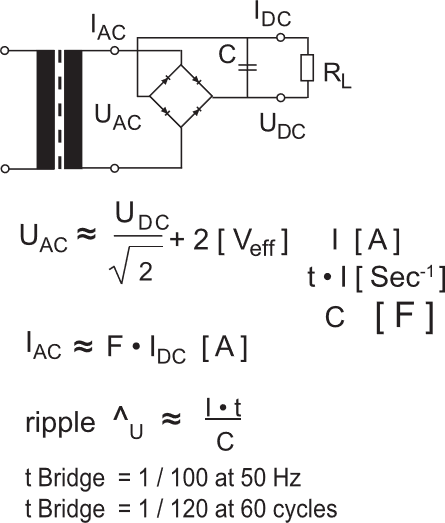

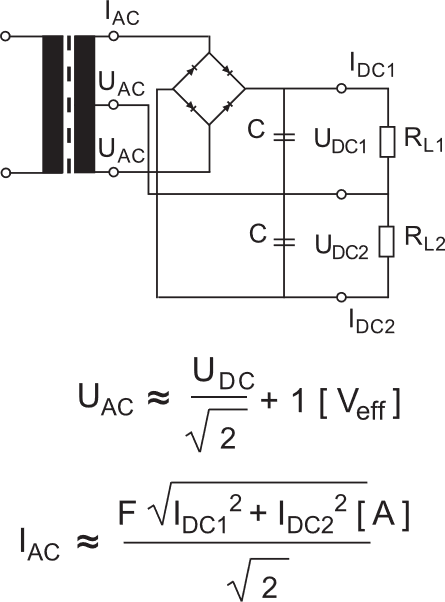

Rectifying

Figures 7 and 8 give formulae for calculation of approximate values of the transformers and are primarily dependent on the size of the loading capacitor to be used. The applied form factor “F” is rated between 1.1 for smaller capacitors and up to 2.5 for for relatively large capacitors.

Safety

Standard Talema transformers are designed and built according to the requirements of European standard EN61558. Being independently tested and approved by DEKRA Certification they carry the KEMA-KEUR and ENEC markings. EN61558 (VDE 0570, IEC 61558) replaced the older EN60742 transformer standard and is referenced as the transformer requirements for many equipment standards in many different product categories. Additionally,upon request we offer toroidal transformers to other specific standards, be they European (EN), American (UL), Canadian (CSA) or worldwide (IEC) standards, covering many applications including Medical equipment, Office equipment, Instrumentation & Control systems, Climate control, Security systems, Professional & Domestic audio & video equipment, and renewable energy systems.

Current Transformers

Current transformers are an efficient, easy to use, and cost effective way to sense current. Applications include circuit control, current and power measurement, and load fault detection. A wide variety of current transformers types with different turns ratios, current ratings, package sizes and accuracies are available.

Current Transformer Training Module

This brief presentation from our friends at Digi-Key provides background and application data for current transformers and discusses the advantages of the different current transformer types.

Understanding Current Transformers

Our Technical Blog has an Introduction To Current Transformers article, which may be of interest.

Change Notification

Product Change Notification

Moisture Sensitive Level : MSL-1

Toroidal Transformers

Current Transformers

Change Notification